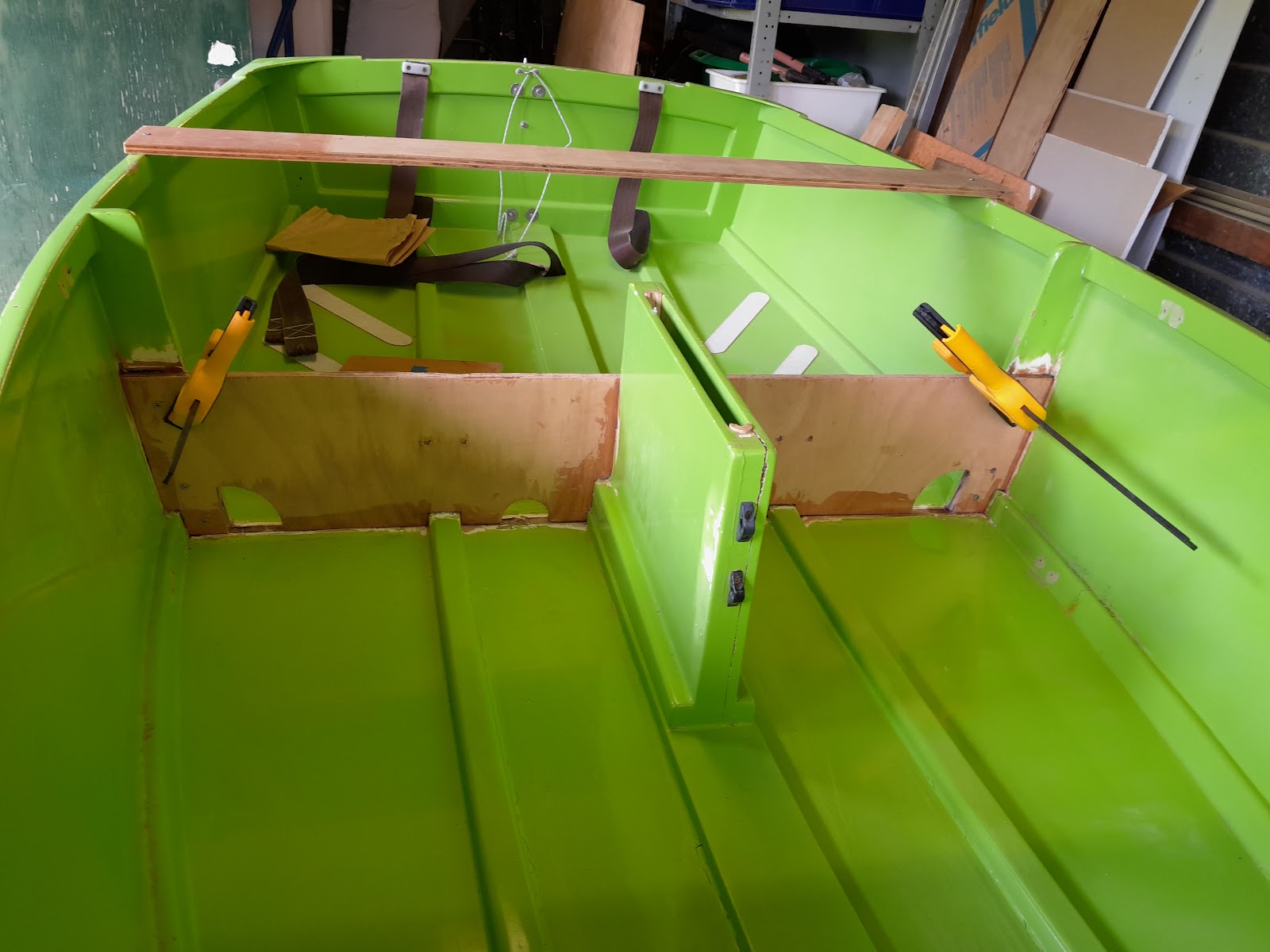

Bulkhead in. Yeah... This was supposed to be my winter project but procrastination, spending way too much time worrying about how to do it rather than doing it, doing one or two things around the house and kicking of LTS for the season meant it isn't done yet. But this is a milestone. Today I put in the new bulkhead. It has screws into the uprights at the side, into the centercase and in through the bottom. This last one was one of the major procrastination worry points. Originally, the screws would have just gone through the stringers in the bottom into the bulkhead, before the ply was put on the bottom of the boat so I wasn't supper happy about putting holes in the ply... But it didn't really feel as though it was going to be held well enough so I drilled the holes. That basically concludes the bits that need more than some filler and paint! This bit was from a while back but didn't get blogged. The centre case pretty much came apart in my hands. I knew the top of